Well, we ended up out of the water in Arrecife boatyard for forever nearly three months. We made a crucial error in believing the boatyard’s estimate of five weeks for the works they were undertaking. We should have added both an “it’s a boat”-premium and a mañana-premium to that and had more realistic expectations. In the event, the long delay has given us the opportunity to get through a whole host of other boat-related jobs. Arthur, 5, when chatting to me at 4am after dragging me to his room for a snuggle, now asks what jobs he can help with tomorrow. Yes, child labour is alive and well in our family. Although he is not allowed up the scaffold with me anymore. When the yard staff are around 😉.

Anyway, we are all well, the boat is in the best condition it has been since we bought it, and we are just-about ready for crossing the Atlantic (once our fuel injectors come back, serviced, from the workshop). Which I realised we have not blogged about, hence this update.

Shall we cross the Atlantic?

Given we now have a baby beginning to crawl and attempting to stand, along with our two other young children, it seems sensible for us to head on a 2800 mile or so passage across an ocean, before sailing somewhere in the region of 5-7000Nm over the ensuing 8/9 months to get back to the UK and my job. And the funny thing is, given that nearly everyone in the marina at present is headed across an ocean, an “Atlantic circuit” sounds positively normal to us now (it’s the “job” bit that sounds odd). There were some rational reasons for heading this way. Chiefly, it’s with the wind rather than against it (which makes sailing much, much more comfortable on our boat). Secondly, winter in the Caribbean can be spent at anchor rather than marinas as we would be in Morocco/Spain/Portugal – which is both more pleasant both for us and our budget.

The decision was made in a very sensible and thought-through way – I was chatting to Charlotte after a long day of sanding the topsides of the boat in 30-degree heat and Sun, and I said “why were we NOT crossing the Atlantic again?”. We didn’t have a good answer, and two days later had started to research which way we would come back from the Caribbean to the UK in 2019.

Planning and preparing for the crossing

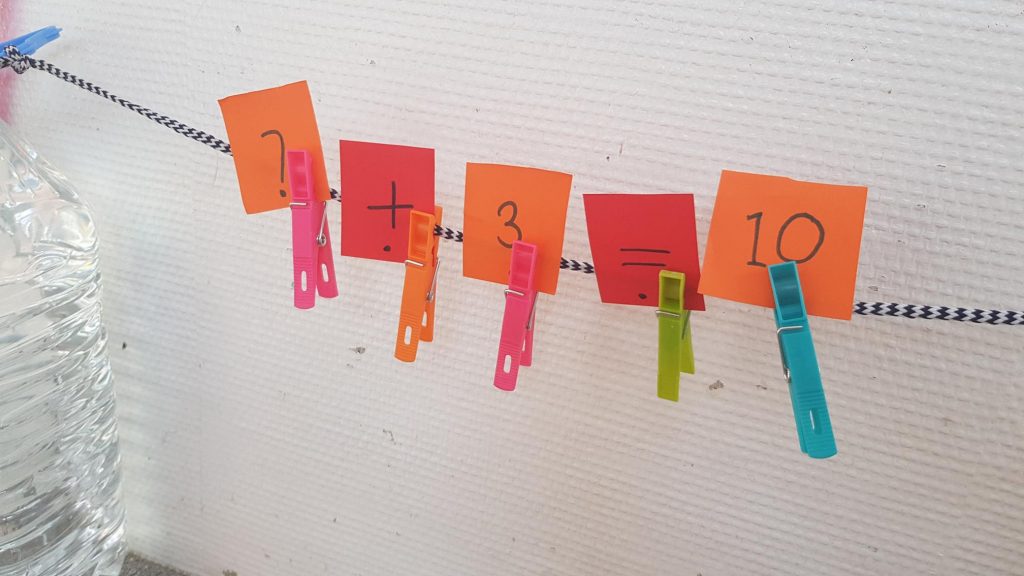

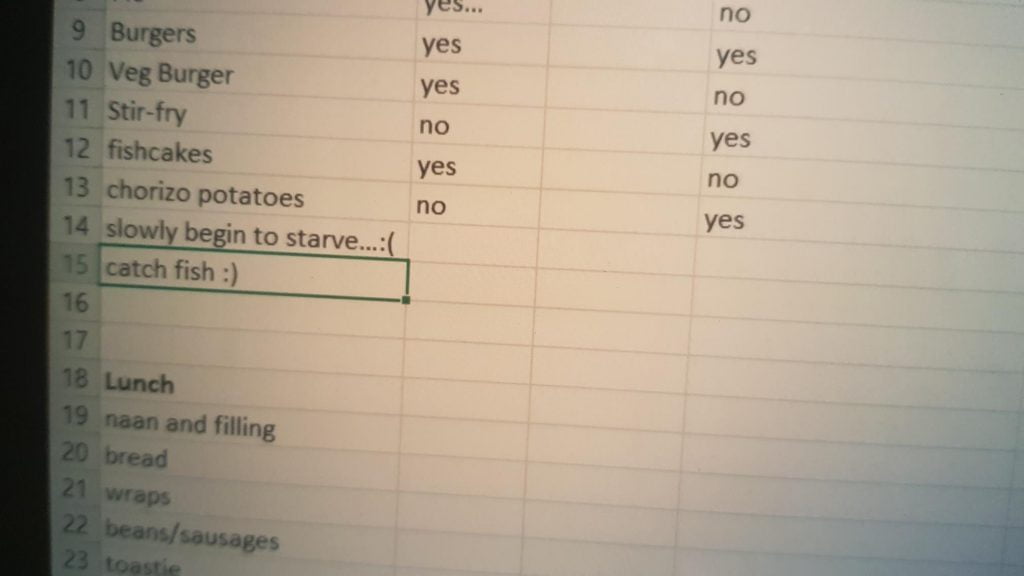

Crossing the Atlantic at this time of year from the Canaries isn’t actually that difficult, as far as the sailing is concerned. We’ll sail South-West for a few days before deciding whether to stop off at the Cape Verdes – that will depend on how much we are enjoying being at sea, along with whether Arthur and Theo have destroyed our food supplies in a ill-fated (but, I’m sure, enjoyable) game. Assuming we’re having fun and not food-less, once we are in the trade winds we can set course straight for Barbados and leave the autopilot to do the work. If we are going via the Cape Verdes it’ll be two trips, one of just under a week and the other of around two weeks. Direct should be around three weeks.

We have set twin headsails up on the jib – using one halyard so they can be furled. Because of our 7m beam, and tracks near the edge of the boat, we can keep both jibs held “out”, one to each side, easily. For downwind sailing this will mean we can easily adjust how much sail we have up (the jib can be rolled away incrementally) – and if hit by a sudden increase in wind speed we can change course a little and pull one jib on top of the other, which would immediately cut the sail area significantly. We’ll try out flying just the jibs or also flying a reefed mainsail. Theo is keen on trying to fly the spinnaker as well, for even more speed, but he doesn’t understand wind shadows – we’ll show him why that wont work.

Our watch-plan is simple, or if anyone from the RYA is reading, negligent. In the day we take random turns depending on who wants to make food / play with the kids / rest on deck. Charlotte takes watch from bedtime until she’s tired. I take over and cat-nap through the night, getting 20 minutes sleep at a time if there’s no reason not to – wake up, look around, do something like check the weather/radar/lines for chafe/make a cuppa, set my alarm and go back to sleep. Then when one of the kids wakes Charlotte up she takes over again and I get a block of sleep. As the kids tend to sleep for longer on passage this works well for us.

Life goes on

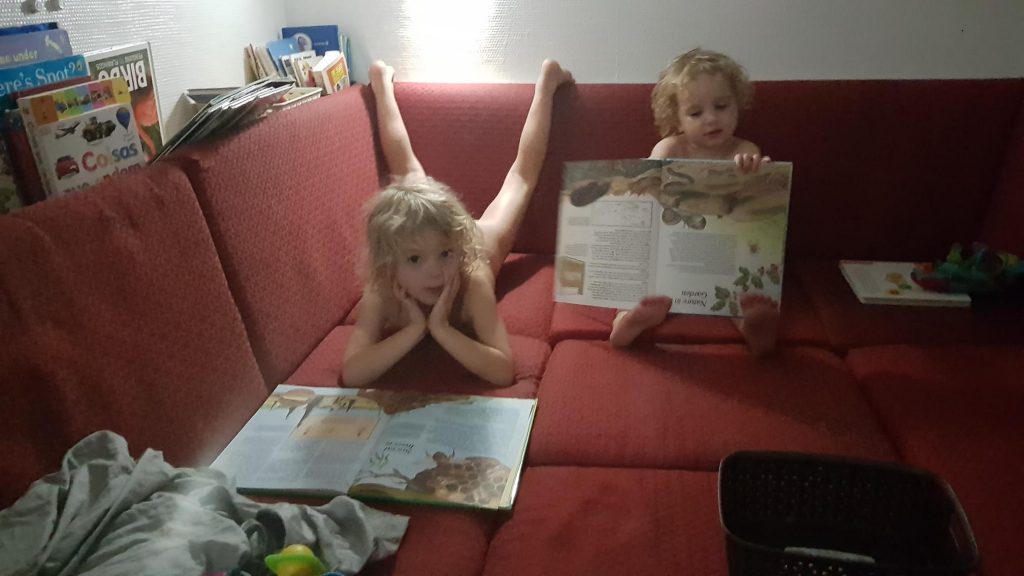

Apart from boat jobs we really have not done much worth writing about over the past couple of months. Hector is happy/healthy, is our first baby who has a sleeping schedule amenable to adults, loves being covered in porridge as well as eating biryani, and wants to be like his big brothers RIGHT NOW. His big brothers are spending their time playing wonderful cooperative imaginative games, acting as scientist/artist pairing while doing the same drawing activity (sorry to those of you familiar with Snow’s two cultures) , digging for fossils by dissecting flatfish at dinner, coming up with innumerable rhyming games (start with “muck” and see what your kids end up shouting after picking up on your reaction), chatting to the yard staff, repurposing selected yard waste (wood, sand etc.), introducing us to other boaties they’ve met, and climbing on everything in sight. Of course, sometimes Theo is setting Arthur’s hair on fire with lava and smashing him to pieces (with words) while Arthur is responding with not-words… they are learning how to wind each other up as well as how to be beautiful together.

sdr

dav

dav

dav

dav

dav

Charlotte has managed not to be driven mad by the kids while I have been doing most of the boat jobs, and is doing more herself now the work is stuff she’s better at and can be done around feeding a baby. I’m half-planning a future as an itinerant boat-builder, starting with building our next boat (with the kids in about 8-10 years) as most days I have enjoyed the work on the boat. For those who are curious I’ve put together a short list of what we have done below along with a few photos – Charlie pointed out that I should have saved my “job list”, but I’m a deleter rather than a strike-througher so it’s lost forever.

Works done by the yard:

- sandblast bottom of boat [after waiting 10 days after an arranged lift out for the sandblaster]

- coat of epoxy primer

- fair bottom of boat [after a painter taught the yard labourers to fair competently – a couple of them are now pretty good]

- 4 more coats epoxy primer

- coppercoat (5 coats)

- Lift the boat to move the supports, and repeat on the bottom of the keels and under previous supports.

Yes, that’s taken nearly three months – we’d recommend the yard for smaller jobs and emergency repairs with no hesitation, but big jobs… be sure they know what they are doing first, or find a contractor who they’ll allow to work in the yard. In any case, as seems to be the case at every boatyard (from conversations with others) it’s best to be on site to manage, nag, correct, etc. etc.

Works done by us:

Sand/fair/undercoat the deck and topsides ready for painting (we had a professional spray the final coats on the topsides) – this has cost us in the region of 6k for materials and Jose’s labour, plus six weeks of my time, and looks bonito. We were quoted 40k for a professional job, which may have been marginally better (depending on the professional), but I can live with the two bits of filling I somehow missed, the fact you can still see the panel shapes on a couple of sections of hull, and my idiocy in not accounting for the different size of our new opening window.

Remove and later re-fit each and every fitting on the boat – properly. We had a couple of minor leaks, which on a cored boat can be very bad news indeed, so we took this opportunity to check EVERYTHING. This involves drilling out a larger hole than needed, filling that with thickened epoxy, drilling a hole the right size, tapping it to accept a threaded machine screw, slathering the bottom of the fitting in sealant and screwing down to leave a gasket of sealant, screwing down, then adding backing plates/washers/nuts.

The windows were a pain (a few were leaking so even if we were not painting they needed attention) – each one has about 20 screws in, which is about 16 more than they need. But without replacing the windows themselves we had to put them all back in. We’ve used a solid rubber strip as a gasket, tightened them enough so there are no leaks with just that, and will add a Sikaflex lip around the edge as insurance. I should mention that it does rain the Canaries, as we found out when a thunderstorm struck when we had no windows in… there was 3” of water in each of the bilges. Whoops.

Replace all of the through hulls with Forespar marelon – seacocks below water line, through-hulls above. The corrosion on one of the old “seacocks” – what looks like a domestic ball-valve that was installed below the waterline – was, well, not good… Two redundant through-hulls were filled using fiberglass in concentric circles either side of a core which was glued in place using thickened epoxy. Did some bits of plumbing connected to this.

Repair the rudders, which are made of plywood with a fiberglass shell. There was a little water in the bottom of one, and a little more in the other (along with some minor rot). This needed draining, digging out, filling, and I’ve strengthened the bottom of the rudders with a few layers of fiberglass tape which will act as a shoe for when the boat is next sitting on the beach.

Other smaller jobs we did at the same time included:

- Prep, epoxy prime, antifoul the saildrives.

- Serviced the engines and propellers.

- Soldered a new BMS onto our lithium-ion batteries.

- Various minor works on the rig – cut off the end of the jib halyard which was chafing, replace the main halyard and one reefing line, install a new U-bolt for the babystay, re-tension everything, move a couple of winches, replace jib furler line and sheets, etc.…

- Installed an Iridium Go with external aerial.

- Built a new tilting mount for each of our solar panels, which were previously hung off the guard rails. And a more secure arrangement for the stern solar panels, which were previously held together by wood, lashing, and hope.

- Charlotte visited the top of the mast a few times to: fit a masthead tricolor (the existing nav lights also lit up our bow netting which was terrible for night vision), fix our non-functioning wind transducer which measures the wind speed (we had thought, on our last few sails, that it was showing a lower wind speed than we were experiencing – that might have been the plant trying to grow inside it).

dav

dav

dav

dav